PI (POLYIMIIDE) Powder, usha, xaashi, alaabooyinka naqshadeynta cnc

Polyamides-ga heerkulka waxaa lagu yaqaanaa xasilloonida kuleylka, iska-caabbinta kiimikada wanaagsan, guryaha farsamada wanaagsan, iyo midab oranji ah / midab jaalle ah. Polybamides oo lagu dhejiyay jaantusyada ama xoojinta dhaballada fiber-ka ah waxay leeyihiin awooda dabacsanaanta ee dabacsanaanta illaa 340 MPA (49.000 PSI) iyo dabacsanaanta Moosha ee 21,000 ee MPA (3,000,000 PSI). Themesos polymer polymer polymer polyamides ayaa muujinaya awood aad u hooseeya oo aad u sarreeya. Guryahaan waxaa lagu hayaa inta lagu jiro isticmaalka joogtada ah ee heerkulka illaa 232 ° C (450 ° F) iyo dalxiisyo gaagaaban, sida ugu sarreeya 704 ° C (1,299 ° F). [11] Xayawaanka polyamimide ee polyamimide iyo dhalmadeedu waxay leeyihiin iska caabbinta kuleylka aad u wanaagsan. Heerkulka heerkulka caadiga ah ee qaybaha noocaas ah iyo kaladuhu wuxuu u dhexeeyaa qaybo ka badan kuwa ka sarreeya 260 ° C (500 ° F). Polybamides sidoo kale waa mid asal ahaan u adkaysata ololka ololka oo badanaa looma baahna in lagu qaso dib-u-dhacyada ololka. Intooda badan waxay ku wataan qiimeynta UL ee VTM-0. Polymimidemetes wuxuu leeyahay nolosha xoogga kala badhka ah ee 249 ° C (480 ° F) oo ah 400 saacadood.

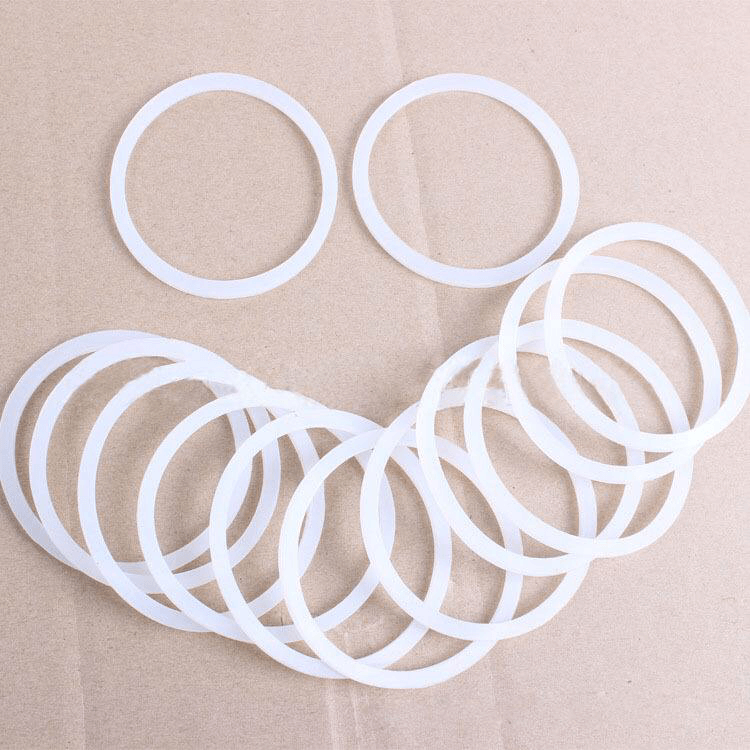

Qeybaha caadiga ah ee polyide ah ma saameeyaan xabiyada iyo saliidaha si caadi ah loo isticmaalo - oo ay ku jiraan hydrocarbons, esters, aalkolo, aalkolo iyo frees. Waxay sidoo kale iska caabiyaan aashitada daciifka ah laakiin laguma talinayo in lagu isticmaalo jawiga ay ku jiraan alkalis ama astaliyada torganic. Qaar ka mid ah polyaamides, sida cp1 iyo corin xls, ayaa ah xallinta iyo soo bandhigaan caddeyn heer sare ah. Guryaha jilicsan ayaa ku amaahiya codsiyada buufin iyo codsiyada dawaynta heerkulka hooseeya.

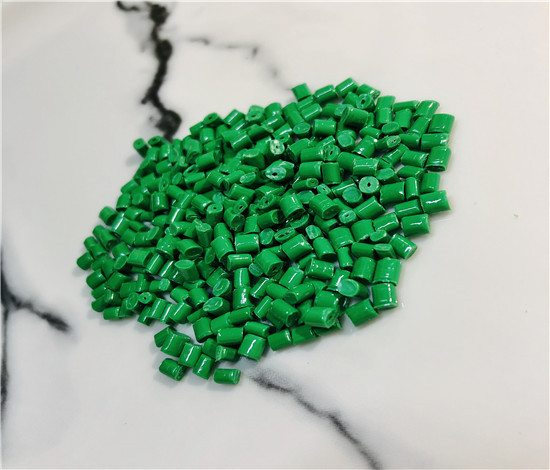

PI

PI waa polymader olole u ah ololkeeda, oo aan ku gubin heerkul sare

Guryaha farsamada ee heerkulka

Maaddadu waxay leedahay awood midabeyn heer sare ah, waxay gaari kartaa shuruudaha kala duwan ee midabka midabka

Waxqabadka kuleylka ee aad u fiican: Heerkul sarreeya iyo iska caabin heerkul hooseeya

Waxqabadka korantada ee aan fiicnayn: Kartida korantada ee sare

Goobta Codsiga Arjiga Dhexe ee PI

Waxaa si weyn loogu isticmaalaa mashiinnada, aaladda baabuurta, korantada iyo elektiroonigga, mashiinnada guriga, ashyaa'da dharka lagu sameeyo, taangiyada shidaalka, taangiyada saxda ah iyo waxyaabaha saxda ah ee injineerinta.

Qalabka polbamimime-ka waa kuwo khafiifa, dabacsan, u adkaysata kuleylka iyo kiimikooyinka. Sidaa darteed, waxaa loo isticmaalaa warshadaha elektiroonigga ah ee fiilooyinka dabacsan iyo sida filim aan ahayn in lagu muujiyo saqafka magnetka. Tusaale ahaan, kumbuyuutar laptop ah, fiilada ku xiraya guddiga macquulka ah ee ugu weyn ee shaashadda (oo ay tahay in la duubo markasta oo laptop-ka la furo ama la xidho) badanaa waa saldhig polkimide ah oo leh kuwa polkimide-ka ah. Tusaalooyinka filimada polyamimime waxaa ka mid ah apical, kapton, sarelex, vtec pi, norton th iyo Kaptrex.

Isticmaalka dheeriga ah ee resin ee polyanmime ah waa sida caymis iyo lakabka xaasidnimo ee soo saarista wareegyada isku dhafan iyo chips mems. Lakabyada polyamimide waxay leeyihiin cirif farsamo wanaagsan iyo awood maroodi ah, oo sidoo kale ka caawiya kudhigga u dhexeeya lakabyada polyamimide ama inta udhaxeysa lakabka polyamimide iyo lakabka birta.

| Beer | Kiisaska dalabka |

| Qeybta Word | Heerkulka sare ee heerkulka sare, saliidaha kombiyuutarka, piston paston, xir xir |

| Qalabka korantada | Hiitarka, taageere qaboojiyaha, xaashida albaabka, daboolka shidaalka shidaalka, hawada hawada, daboolka haanta biyaha, laambadda laambadda |

Fasalada SPLA-3D iyo sharraxaadda

| Heer u qaybin | Sifo |

| Spla-3d101 | Pla-ka sarreeya ee waxqabadka. PLA xisaabaadka in kabadan 90%. Daabacaadda daabacaadda wanaagsan iyo xoojinta xoojinta. Faa'iidooyinka ayaa ah mid deggan oo deggan, daabacaadda jilicsan iyo guryaha wanaagsan. |

| Spla-3dc102 | PLA xisaabaadka 50-70% oo inta badan waa la buuxiyaa oo la sii daayaa. Faa'iidooyinka wax lagu sameeyo, daabacaadda jilicsan ee guryaha farsamada gacanta. |