Nylon 66 waxay leedahay sifooyin farsamo oo wanaagsan, xirto iska caabin iyo iska caabin daxalka kiimikaad, waxaana si weyn loogu isticmaalaa meelaha baabuurta, elektiroonigga ah iyo korantada. Si kastaba ha ahaatee, PA66 waa walxo guban kara, waxaana jiri doona dhibco marka gubanaya, taas oo leh khatar weyn oo badbaado ah. Sidaa darteed, waa muhiim in la barto wax ka beddelka ololka ee PA66. Habka dab-demiska ee PA66 waxa hore u ahaan jiray dib-u-dhigeyaasha ololka barafaysan, laakiin dab-demiska ololka ee burburay ayaa la kulmay dhibaatooyin halis ah oo ilaalinta deegaanka ah iyo CTI.

Waqtigan xaadirka ah, dib-u-celinta ololka fosfooraska cas waxaa lagu dabaqi karaa agabka dab-demiska ee PA66 sababtoo ah hufnaantiisa sare ee ololka iyo wax-qabadka qiimaha sare leh. Si kastaba ha ahaatee, fosfooraska cas ayaa dib u dhigaya ololka heerkulka sare, hawada, huurka sare iyo deegaanka alkaline, si sahlan loo nuugo biyaha, taas oo keenta aashitada walxaha. Aashitada fosfooraska ayaa daxalaynaysa qaybaha birta, taasoo keenaysa sifooyinka korantada ee alaabta.

Si looga hortago aashitada falcelinta fosfooraska cas, hagaajinta xasilloonida fosfooraska cas, ilaa hadda habka ugu waxtarka badan waa in microcapsule lagu dahaadhay fosfooraska cas, habkani waa iyada oo la adeegsanayo polymerization-ka goobta, dusha sare ee fosfooraska cas samee maaddo polymer ah oo deggan, si aad uga baxdo xiriirka fosfooraska cas iyo ogsijiinta iyo biyaha, waxayna yareysaa aashitada fosfooraska cas, waxay kordhisaa xasilloonida isticmaalka walxaha.

Si kastaba ha ahaatee, resins daahan kala duwan ayaa saameyn kala duwan ku leh naylon xoojiyay olol fosfooraska cas. Daraasaddan, laba dib-u-kicinta ololka fosfooraska cas oo lagu dahaadhay resin phenolic iyo resin melamine ayaa loo doortay si ay u daraaseeyaan saamaynta labadan dab-demiska ee kala duwan ee sifooyinka kala duwan ee dab-demiska ee kor loo qaaday PA66.

Halabuurka aasaasiga ah ee maaddadu waa sida soo socota: melamine resin dahaarka cas fosfooraska holac retardant Master material (MC450), phenolic resin dahaarka cas cas ee holac fosfooraska wax sayidkiisa (PF450): content fosfooraska cas ee 50%. Samaynta naylon dib-u-celinta ololka ee la xoojiyay 66 waa 58% naylon 66, 12% walxo sayid oo olol ah, 30% fiber galaas ah.

Dib-u-dhigista ololka fosfooraska cas ee dahaarka leh ayaa kor loo qaaday xaashida caanaha ee PA66

| Tusaalaha No. | PA66 | MC450 | PF450 | GF |

| PA66 - 1 # | 58 | 12 | 0 | 30 |

| PA66 -2# | 58 | 0 | 12 | 30 |

Isku darka iyo wax ka beddelka ka dib, isku-dhafka PA66/GF30 ee lagu dahaadhay ololka fosfooraska cas ayaa la diyaariyey, sifooyinka la xidhiidhana waxaa loo cabbiray sida soo socota.

1. Dib u dhac ololka, heerkulka siliga kulul iyo tusmada calamadaha qariibka ah

| Tusaale | 1.6 mm | Dhicis | GWFI | GWIT | CTI |

| Tirada | Heerka gubashada | Xaalada | / ℃ | / ℃ | / V |

| PA66-1# PA66-2# | V -0 V -0 | no no | 960 960 | 775 775 | 475 450 |

Waxaa la arki karaa in labadaba PA66-1 # iyo PA66-2 # ay gaari karaan darajada dib u dhigista ololka ee 1.6mm V-0, agabkuna ma daataan xilliga gubashada. Labada nooc ee dahaarka leh ee ololka fosfooraska cas ee dahaaran ee PA66 la xoojiyay waxay leeyihiin saameyn dib-u-dhigis aad u wanaagsan. Tilmaanta ololka iftiimaya (GWFI) ee PA66-1# iyo PA66-2# waxay gaari kartaa 960℃, GWIT-na waxay gaari kartaa 775℃. Waxqabadka gubashada tooska ah iyo waxqabadka tijaabada fiilada dhalaalaysa ee labada qalab ee fosfooraska cas ee dahaarka leh ee dahaaran ololka waxay gaari karaan heer aad u wanaagsan.

Waxa kale oo la arki karaa in PA66-1 ay waxyar ka sarrayso CTI-ga # PA66-2 #, iyo CTI ee labada shay ee fosfooraska dahaarka leh ee dab-demiska ah ee PA66 ay ka sarreeyaan 450V, kaas oo buuxin kara shuruudaha codsiga ee warshadaha intooda badan.

2. Hantida makaanikada

| Tusaale Tirada | xoog adkaysi | xoog laabasho | xoogga saamaynta/(kJ/m2) | |

| /M Pa | /M Pa | Farqiga | Darajo malaha | |

| PA66 - 1 # | 164 | 256 | 10.2 | 55.2 |

| PA66 -2# | 156 | 242 | 10.5 | 66.9 |

Guryaha makaanikada ayaa ah sifooyinka aasaasiga ah ee muhiimka ah ee naylon la xoojiyay ee ololka si loo isticmaalo.

Waxaa la arki karaa in xoogga jilicsanaanta iyo xoogga foorarsiga ee PA66-1 # ay ka sarreeyaan, kuwaas oo ah 164 MPa iyo 256 MPa siday u kala horreeyaan, 5% iyo 6% ka sarreeya PA66-1 #. Awoodda saamaynta muuqata iyo xoogga saamaynta aan la garanayn ee PA66-1 # labaduba way sarreeyaan, kuwaas oo ah 10.5kJ/m2 iyo 66.9 kJ/m2 siday u kala horreeyaan, 3% iyo 21% ka sarreeya kuwa PA66-1 #, siday u kala horreeyaan. Qalabka guud ee farsamada ee labada qalab ee lagu daboolay fosfooraska cas ayaa sarreeya, kaas oo buuxin kara shuruudaha waxqabadka ee beeraha kala duwan.

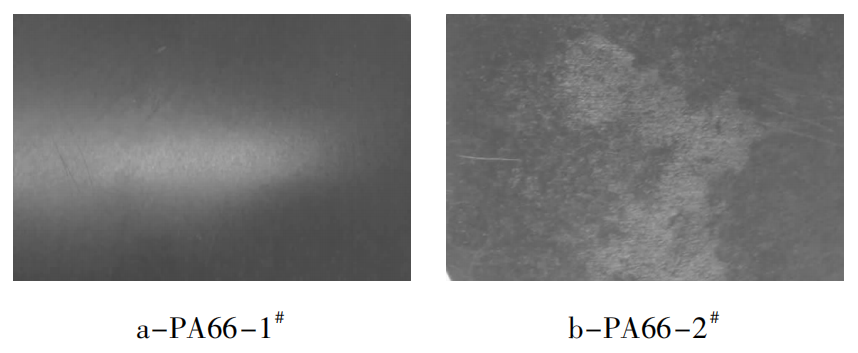

3. Muuqashada iyo urta

Waxaa laga arki karaa muuqaalka laba nooc oo muunado qaabaysan oo la isku duro oo lagu dahaadhay fosfooraska cas, in dab-dejinta ololku kor u qaaday PA66 (PA66-1#) oo lagu diyaariyey resin melamine oo lagu dahaadhay fosfooraska cas ayaa leh dusha siman, midab dhalaalaya oo aan lahayn fibre sabaynaya dusha sare. Midabka dusha sare ee dab-demiska ayaa xoojiyay PA66(PA66-2#) oo ay diyaarisay xabagta phenolic ee dahaarka leh ee fosfooraska cas ma ahayn labbis waxaana jiray fiilooyin sabeynaya. Tani waa inta badan sababtoo ah resin melamine laftiisa waa budo aad u fiican oo siman, sida lakabka daboolka ah ee la soo bandhigay, wuxuu ka ciyaari doonaa doorka saliidda ee nidaamka walxaha oo dhan, sidaas darteed muuqaalka maaddada waa mid siman, ma jiro fiil sabeynaya.

Laba nooc oo fosfooraska-dahaarka cas cas ee dib-u-celinta ololka ee la xoojiyay ee walxaha PA66 ayaa lagu meeleeyay 80 ℃ 2 saacadood, cabbirkooda ur waa la tijaabiyay. Pa66-1 # walxaha waxay leeyihiin ur cad iyo ur daran. Pa66-2 # wuxuu leeyahay ur yar oo aan lahayn ur cad. Tani waxay inta badan sabab u tahay dahaadhka goobta ku yaal, unugyaraha yar yar ee amine-ku dahaaran ma fududa in si nadiif ah looga saaro, iyo urta walaxda aminiga lafteeda ayaa weyn.

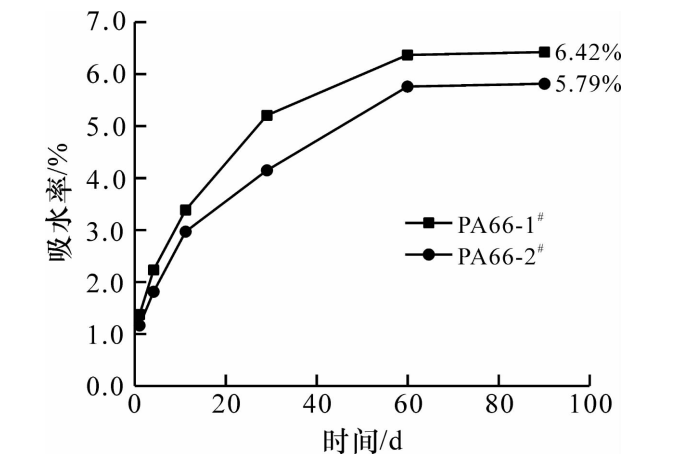

4. nuugista biyaha

Sababtoo ah PA66 waxay ka kooban tahay amine iyo kooxaha carbonyl, way fududahay in la sameeyo bonds hydrogen leh molecules biyaha, sidaas darteed way fududahay in la nuugo biyaha marka la isticmaalo, taasoo keentay saameyn balaastig ah, taasoo keentay balaadhinta mugga alaabta, hoos u dhaca qallafsanaanta, iyo qulqulka cad ee hoos yimaada ficilka stress.

Saamaynta fosfooraska cas ee ololka dahaaran ee kala duwan ku leeyahay nuugista biyaha ee walxaha ayaa la darsay iyadoo la tijaabiyay nuugista biyaha ee walxaha. Waxaa la arki karaa in nuugista biyuhu ee labada shay ay kordhiyaan korodhka wakhtiga. Nuugista biyaha bilowga ah ee PA66-1 # iyo PA62-2 # waa isku mid, laakiin kororka wakhtiga nuugista biyaha, nuugista biyaha ee walxaha kala duwan ayaa iska cad inay kala duwan yihiin. Waxaa ka mid ah, naylon fosfooraska dahaarka leh ee phenolic-ka cas (PA66-2#) ayaa leh heerka nuugista biyaha hoose ee 5.8% 90 maalmood ka dib, halka melamine resin dahaarka casaanka ah ee ololka fosfooraska cas (PA66-1#) uu leeyahay biyo xoogaa ka sarreeya. heerka nuugista 6.4% ka dib 90 maalmood. Tani waa inta badan sababtoo ah phenolic resin laftiisa heerka nuugista biyaha ayaa hooseeya, iyo xuubka melamine waa nuugista biyaha xoog leh, caabbinta hydrolysis waa mid liidata.

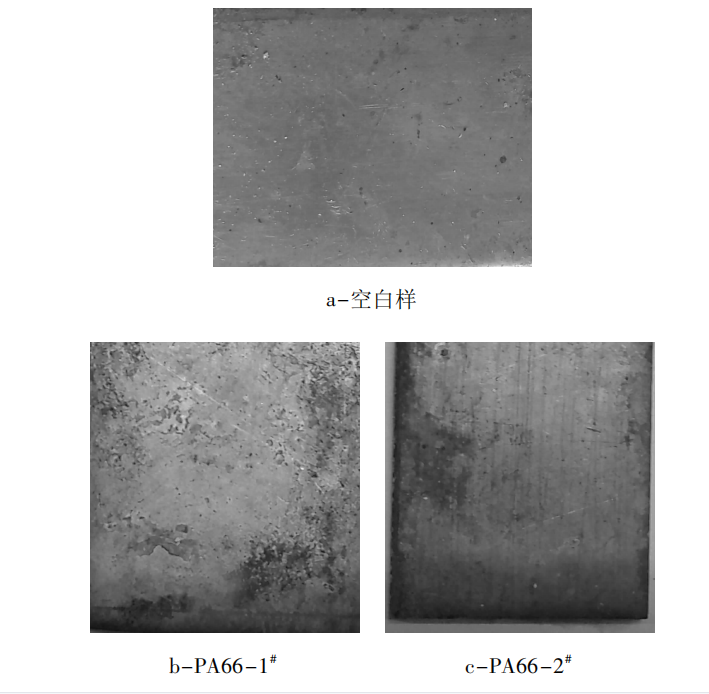

5. Iska caabinta daxalka ee birta

Laga soo bilaabo shaybaarrada bannaan iyo ilaa kala duwan oo dahaarka leh holac fosfooraska cas oo kala duwan oo la xoojiyay walxaha nylon ee daxalka birta ee shaxanka ayaa arki kara, ma aha in lagu biiro, muunadda bannaan ee daxalka dusha birta naylon ee la beddelay ayaa ka yar, waxaa jira hawo yar iyo uumiga uumiga biyaha oo ay sababtay calaamad, PA66-1 # ee daxalka birta waa mid aad u wanaagsan, dhalaalka dusha birta ah ayaa ka fiican, qaybo yar ayaa leh ifafaale daxalka, Daxalka birta ee PA66-2 # ayaa ah midka ugu daran, dusha sare ee xaashida birta ayaa si buuxda u wasakhoobay. , halka dusha sare ee xaashida naxaasta ah ay daxalantahay oo si cad u midabaysan yahay. Tani waxay tusinaysaa in daxalka xabagta melamine ee dahaarka leh ee naylon ololka fosfooraska cas ee dahaarsan uu ka yar yahay kan xabagta phenolic ee dahaarka leh ee naylon dib u ololaysa ee fosfooraska cas.

Gabagabadii, laba nooc oo ah agabka PA66 ee la xoojiyay ololka ayaa la diyaariyay iyadoo lagu dahaadhay fosfooraska cas oo leh resin melamine iyo resin phenolic. Labada nooc ee alaabta ololka celisa waxay gaari karaan 1.6mmV-0, waxay dhaafi karaan 775 ℃ heerkulka dab-damiska, iyo CTI waxay gaari kartaa in ka badan 450V.

Xoogga jilicsanaanta iyo xoogga dabacsanaanta ee PA66 ayaa lagu xoojiyay melamine-ka dahaaran fosfooraska cas, halka saameynta hantida PA66 ay ku fiicnaatay fosfooraska cas ee dahaarka leh. Intaa waxaa dheer, urta resin phenolic ee lagu dahaadhay ololka fosfooraska cas ee PA66 ee la xoojiyay ayaa ka yarayd tan walxaha dahaarka leh ee melamine, heerka nuugista biyuhuna wuu yaraa. Xabagta Melamine ee lagu dahaadhay retardant olol fosfoor guduudan waxay wanaajisaa muuqaalka PA66 oo leh daxal yar oo biraha ah.

Tixraac: Daraasad ku saabsan guryaha dib u dhigista ololka ee PA66 oo lagu dahaadhay fosfooraska cas, agabka internetka.

Waqtiga boostada: 27-05-22