Masaarooyinka injineeriyada khaaska ah ee loo yaqaan 'Injineeriyada Injineeriyada' Tilmaamaha Injineeriyada ee loo yaqaan 'Injineeriyada' oo leh dhismayaal dhameystiran iyo heerkulka adeegga muddada-dheer ee ka sarreeya 150 ℃. Guud ahaan labadaba is-caabbinta heerkulka sare, caabbinta shucaac, hafsinta hydrolysiy, iska caabbinta cimilada, iska caabbinta cimilada, qulqulka dabiiciga ah, heerka kuleylka dabiiciga ah, caabbinta kuleylka iyo faa'iidooyinka kale. Waxaa jira noocyo badan oo ah balaastigyo injineer qaas ah, oo ay kujirto polyyliququid polymone (LCP), POLYIMIME (POSENLE POLYLONE (PSYULFONFIDE (POSESULFONFIDE (POSESUROLYMYS), Passulfoodsers (PTFE, PVDF, PCTFE, PFA), iwm.

Marka laga eego aragtida taariikhda iyo xaaladda hadda jirta, wadamada yurub iyo Mareykanka ee ka soo baxay Polyime 1960-yadii iyo soo-celinta polyritther-ka sanadkii 1980-meeyadii, ilaa hadda ay sameeyeen wax ka badan 10 nooc oo ah balaastigga caasimada injineernimada qaaska ah. Baaskiillada Injineeriyada Khaaska ah ee Shiinaha ayaa ka bilaabmay dhexda iyo dhammaadka 1990-yadii. Waqtigan xaadirka ah, warshaduhu waxay ku jirtaa marxaladda koowaad ee horumarka, laakiin xawaaraha horumarka waa dhakhso. Dhowr balaastigyo injineernimo gaar ah oo gaar ah ayaa loo qaataa tusaale ahaan.

Qulqulka dareeraha dareeraha ah (LCP) waa nooc ka mid ah qalabka polyester-ka udgoon ee ay ku jiraan qaab dhismeedka giraan ah ee Benzene ee ku saabsan silsiladda ugu weyn, oo ku beddeli doonta qaab dareere ah oo kululaynta, oo ay leedahay guryo dhammaystiran oo dhammaystiran. Waqtigan xaadirka ah, awoodda caalamiga ah ee culujiyadda dareeraha ah ee dareeraha ah waa qiyaastii 80.000 tan / sanadka, iyo Mareykanka iyo Japan oo qiyaastii ah 80% awooda guud ee guud ahaan adduunka. Warshadaha LCP ee Shiinaha ayaa soo daahay, iyadoo wadarta guud ee wax soo saarka ee hadda jirta ee qiyaastii 20,000 tan / sanadka. Soo-saareyaasha ugu waaweyn waxaa ka mid ah biyo cusub oo aan lahayn walxaha cusub, Zhuhai Vantone, Shangbo Jujia, iwm. Baahida qalabka elektiroonigga ah iyo qalabka korantada iyo waaxaha gawaarida.

Poly Pronetherther Dethene Ketone (Peek) waa mid-qudhun, shey bayaanno udgoon ah oo loo yaqaan 'polymotas poly poly poly'. Waqtigan xaadirka ah, waxaa suuqa ku yaal sedex nooc oo polythietletthertletletletthertletlet, resin saafi ah, fiber dhaxan oo wax laga beddelay, kaarboon kaarboon ayaa wax laga badalay. Waqtigan xaadirka ah, Wiggs waa soo-saareyaasha adduunka ee loo yaqaan 'polyetherther', oo leh awood wax soo saar oo qiyaastii ah 7000 tan / sanadka, oo ay ku xisaabtamaan qiyaastii 60% awoodda guud ee awooda adduunka. Horumarinta tikniyoolajiyada ee Pololojiyadda ee Shiinaha ayaa soo daahay, oo awoodda waxsoosaarka ayaa inta badan ku saleysan Zhongyan, Zhejiang Pengfu muddo dheer iyo Jida te balaastikada, oo ay ku xisaabtamayaan 80% wadarta awoodda soosaarka ee Shiinaha. Waxaa la filayaa in shanta sano ee soo socota, baahida loo qabo China ee ku yaal Shiinaha ayaa hayn doona heerka koritaanka ee 15% ~ 20% oo uu gaaro 3000 tan 2025.

POLYIMIIDE (PI) waa xarun polycycer polymocycle heremoocycle oo ay ku jiraan imikada silsiladda ugu weyn. Toddobaatan boqolkiiba wax soo saarka caalamiga ah ee PI ayaa ku yaal Mareykanka, Japan, South Korea iyo wadamada kale. Filimka PI sidoo kale waxaa loo yaqaanaa "filim dahab ah" qaab ciyaareedkiisa wanaagsan. Waqtigan xaadirka ah, waxaa ku jira ilaa 70 soo saareyaal filim oo Polyamimide ah, oo leh wax soo saarka wax soo saarka oo qiyaastii 100 tan ah. Waxaa inta badan loo isticmaalaa suuqa ugu hooseeya, halka cilmi baarista madaxa bannaan iyo heerka horumarka ee badeecadaha ugu sareeya aysan sareynin, oo inta badan waa la soo dejiyaa.

PPS waa mid ka mid ah kuwa ugu muhiimsan ee caanka ah ee polyaryl suldhiska sulfide. PPS waxay leedahay wax qabad kuleyl heer sare ah, waxqabadka korantada, caabbinta kiimikada, caabbinta shucaaca, dib u dhigista ololka iyo guryaha kale. PPS waa caag heer sare ah oo injineer ah oo heer sare ah oo leh wax qabad dhameystiran oo heer sare ah iyo wax qabad qaali ah. PPS waxaa badanaa loo isticmaalaa maaddaama shey qaab-dhismeedka qaabdhismeedka ah. Waxaa si weyn loogu isticmaalaa gawaarida, elektiroonigga ah iyo korantada, kiimikada, mashiinka, hawada, warshadaha nukliyeerka, warshadaha cuntada iyo maaddooyinka kale.

Laga soo bilaabo goobta arjiga, balaastikada injineerinka qaaska ah ee lagu daro arjiga elektiroonigga ah, baabuurta, aaladaha talooyinka ee cusub, iskucelceliska tamarta, polaterka cadaadiska, semiconductor, daryeelka caafimaadka, tamarta. Iyo warshadaha kale, oo leh horumarinta deg-degga ah ee loo adeegsado balaastigga injineeriyada qaaska ah sidoo kale waa fiditaanka, qaddarka iyo nooca dalabka ay sii kordhayaan.

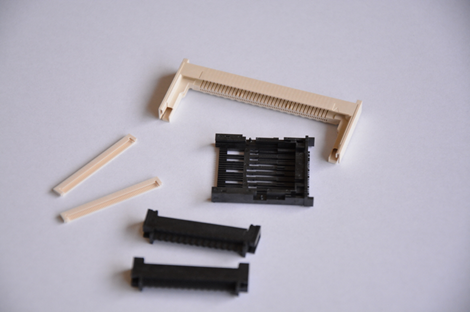

Laga soo bilaabo wax ka badalida-dhexe iyo wax-ka-qabashada, balaastigga injineernimada khaaska ah badanaa waxaa lagu habeeyaa furitaanka galaaska / Karkiga, Liidinta Macdanta, Dheecaanka, xirashada, isku darka caabbinta, iwm, si loo sii wanaajiyo qiimahooda codsi . Hababka ay ka baaraandegayaan iyo qaababka ka dib ayaa ka mid ah wax ka badalida wax-ka-beddelka, caritaanka duritaanka, filimka dib-u-soo-dejinta, is-xakameynta wax-damiska, aaladda farsamada, oo adeegsan doona qalabka waxyaabo kala duwan, iwm.

Waqtiga Post: 27-05-22